Maintenance of machinery used in aquaculture and the advantages and disadvantages of vertical crushing mixer

Among the machines used in breeding, there is a machine that is basically used by farmers who supplement corn.

Vertical crushing mixer

This kind of machine is very common, the structure is relatively simple, the performance is reliable, the performance-to-price ratio is high, the use is frequent, it is one of the essential equipment of the farm.

There are generally two models and feeding modes of this kind of machine, 500 and 1000 (representing the volume weight of the machine, the digital unit is kg). The working modes are self-priming type and spiral lifting strong feeding type, because the strong feeding type is easy to cause the main motor to burn out. Now it is rare. Today, we will introduce the matters needing attention with the 1000 self-priming type.

This kind of machine mainly has self-priming grinder, stirring lifting mixing cage and silo combination. The main part of the self-priming crusher is the suction disk assembly.

The material steel plate used in the wind plate assembly is composed of 45 steel pin and manganese alloy hammer. in the dynamic balance test bench, it is debugged and produced at 3 thousand revolutions per minute and less than 5 grams required for deflection, so as to ensure the uniform force of the motor bearing and improve the service life of the motor. the whole machine does not vibrate in the course of operation, and the phenomenon of running does not occur. The main motor is generally 7.5 to 11 kilowatts 2 poles, rotating speed 2900 / min, through high-speed centrifugal movement to cause suction tube negative pressure, and to achieve self-priming grain into the crushing bin, so that the material in the high-speed environment and hammer impact and crushing, crushing materials below the aperture of the screen, and into the lifting mixing chamber.

The mixing chamber is a spiral lifting mixing, the material to be mixed is added from the lower feed inlet, and the mixing material is transferred from the feed hopper of the vertical mixer to the vertical screw conveyor by the lifting screw in the feed mixer. After it is lifted up to the top, it is thrown by the umbrella, falls around the mixing cylinder, re-enters the vertical screw conveyor from the gap at the bottom of the sleeve, and rises up again. In this way, stir and mix until it is evenly mixed and stored in the silo. Take as you like (stirring motor 3 kW quadrupole 1450 / min).

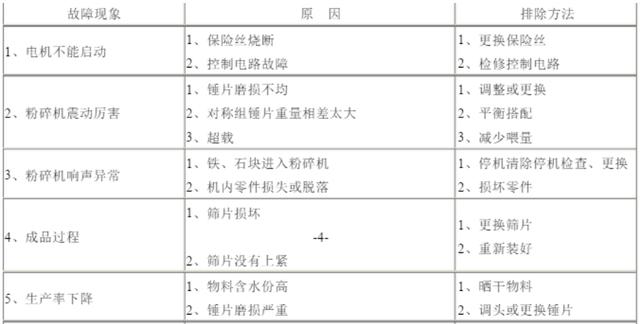

Fault and troubleshooting

For the maintenance of the crushing mixer, it is required to add butter on the main power bearing every six months, check whether the wiring terminal is loose, increase the magnetic magnet to remove iron, indoor installation, rain-proof and so on.

There are the following points to pay attention to the advantages and disadvantages of this machine.

Whether the main motor is a copper-clad motor. As the load of the machine will not be stable, copper cladding must be selected.

Second, the shell of the crusher can be divided into steel plate and cast iron, and the vibration and weather resistance of iron castings is greater than that of steel plate.

Third, the magnitude of vibration during operation is the main way to judge the suction cup balance force. the smaller the vibration is, the better the machine performance is.

Special attention should be paid to the replacement of sucker hammers, which must be numbered first, removed and then weighed and recorded, and then the weight of each group of hammers replaced is equal, otherwise it will cause serious vibration of machinery and equipment and cannot be used.

If there is anything else you don't understand, please leave me a message.

- Prev

How to raise the dance of elegant music? breeding methods and matters needing attention

The propagation of elegant music dance is often done by cutting or grafting. Cuttage is generally carried out in the growing season, cuttings can be pruned during shaping, length requirements.

- Next

Daily evergreen farming, do you pay attention to these six points?

Evergreen leaves, evergreen seasons, winter green leaves with red fruit, elegant and beautiful, eternal youth, health and longevity, friendship everlasting, rich.

Related

- On the eggshell is a badge full of pride. British Poultry Egg Market and Consumer observation

- British study: 72% of Britons are willing to buy native eggs raised by insects

- Guidelines for friendly egg production revised the increase of space in chicken sheds can not be forced to change feathers and lay eggs.

- Risk of delay in customs clearance Australia suspends lobster exports to China

- Pig semen-the Vector of virus Transmission (4)

- Pig semen-the Vector of virus Transmission (3)

- Five common causes of difficult control of classical swine fever in clinic and their countermeasures

- Foot-and-mouth disease is the most effective way to prevent it!

- PED is the number one killer of piglets and has to be guarded against in autumn and winter.

- What is "yellow fat pig"? Have you ever heard the pig collector talk about "yellow fat pig"?