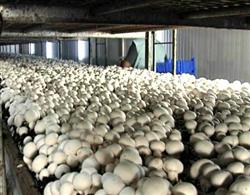

High-yield cultivation of Pleurotus ostreatus in bed frame

1. Mushroom house and bed frame structure mushroom house is 19.6m long from east to west, 9m wide from north to south, 2.5m high from front and rear wall and 3.5m high from gable. The wall is bricked with lime. Put cement on the outside; wipe it with lime mud on the inside, then brush it with lime mud. There are 4 25cm × 20cm ventilation windows up and down the front and rear wall facing the aisle, and the first ventilation window is 20cm from the ground. There are doors at both ends of the front wall, 1.0m wide and 1.8m high, with bricks and cement seams on the ground. The roof is made of bamboo pole film. The bed frame is 7.8m long, 1.5m wide and 2.3m high, with five layers. The first layer is 10cm from the ground, and the spacing of each layer above is 55cm. One east-west aisle near the front wall is 0.7m wide and 10 north-south walkways, each 0.65m wide, with a total cultivated area of 500 square meters. 2. The cultivation time of Pleurotus ostreatus is usually in spring and autumn. The pre-wetting time of wheat straw cultivation in our city is August 5-15, the sowing date is September 5-15, while the pre-wetting time of cottonseed shell is September 10-15, the sowing time is September 15-20. 3. As2796 strain with high yield, strong anti-impurity ability and wide adaptability was selected. 4. Culture material formula (calculated according to the actual cultivation area of 100m2) ① wheat straw 3000kg, fresh chicken manure 3.5m3 (or dried chicken manure 900kg), urea 35kg, calcium superphosphate 35kg, gypsum powder 100kg, lime powder 50kg, calcium carbonate 50kg; ② cotton seed shell 1500kg, special fertilizer 100kg for Pleurotus ostreatus, gypsum powder 30kg, lime powder 15~20kg. 5.1.The fermentation of wheat straw before ①: pre-wetting wheat straw according to the time schedule. The more thoroughly and evenly the pre-wet is, the better, so that it is better to be wet than dry. There are two specific methods: one is to soak in 0.5% lime water in the pre-dug pit, and after absorbing enough water, the chicken manure is removed and proportionally mixed with the pre-piled chicken manure to build a pile; the second is to spread wheat straw 40~60cm on the hard ground and spray water to make it fully absorbed; on the second day, form a 1m high pile and spray 5% lime water around it. Continue to spray water on the third day, and finally make the wheat straw wet and evenly, with a water content of about 60% (pull out a few pieces of wheat straw, wring by hand, and you can see the water oozing). However, we should be careful not to sprinkle lime powder directly in the pre-wetting. Also mix well with the pre-pile of chicken manure. One day before the construction of the pile, sprinkle a layer of lime powder or sprinkle 10% thick lime water at the bottom of the pile. On the second day, urea was evenly added to the mixed wheat straw. At the same time, the partially non-wet wheat straw was soaked in a pre-dug puddle and placed on the top of the pile, stacked north-south, 1.6m-1.8m wide, 2m high, unlimited in length, vertical around, and turtle-shaped at the top of the pile, covering the grass. On the second day, the temperature was measured every 2 to 3 hours. When the temperature rose to 65 ℃, keep for 3 to 4 days, turn the pile for the first time, leave a good ventilation duct or cushion a stick before turning, combine turning the pile, adjust the moisture, make the water content reach about 75% (hold the culture material by hand and drop about 10 drops of water), at the same time, add gypsum powder evenly. When turning the pile, the material is sour, and the pH8.0 can be adjusted with 2% to 5% lime water, the height and width of the pile remain the same, and the length is shortened. Clean up the debris around the heap after turning the heap. The temperature was measured on the second day, and when the temperature rose to 65 ℃, the temperature was kept for 3 days. Turn the pile for the second time. Before turning the pile, wet the culture material around the pile with a sprayer, or concentrate the dry material on the outside of the pile into a piece of water to make it wet through, and put it into the middle and upper part of the pile when turning, the water content is adjusted to about 72%, and the pH value is 7.8. After turning the pile, it was still turned over for the third time after 2.5 days according to 65 ℃. Before turning the pile, also leave the ventilation duct or cushion the stick, aerate and ferment and keep it 2.5-3.0 days. Generally, the water transfer is appropriate, the heap temperature is normal, and the pre-fermentation can turn the heap for 3 times. If the water is not properly transferred, or the material temperature is low, it is necessary to turn the stack for the fourth time. After each turn, the stack surface should be sprayed with 0.5% dichlorvos and 80% deltamethrin 1000 times. ② secondary fermentation (post-fermentation): the secondary fermentation of wheat straw can be divided into two types: the secondary fermentation outside the mushroom and the secondary fermentation inside the mushroom. The secondary fermentation site outside the mushroom room was thoroughly cleaned at first. Then spray 1000 times of deltamethrin and sprinkle a thin layer of quicklime powder (whichever is not exposed to the surface). After building the ventilation duct with bricks (5~8cm between bricks and bricks) and the air extractor (preferably with bricks to form a brick cage with ventilation on four sides), pile the material in the north-south direction with a height of 1.5m, a width of 1.2m, a length of about 20m, with a tortoise back at the top and vertical on all sides. After the stack is built, plug the extractor and cover the stack with plastic film before 9 ∶ 00 on the 2nd. The distance between the film and the culture material is 20~30cm, which can be larger in order to facilitate operation. When the temperature in the distance rises to about 45 ℃, fumigate with appropriate amount of potassium permanganate and formaldehyde. When the temperature rises to 57 ℃ after fumigation, it will be sealed for 8 hours and 10 hours. After strict disinfection, the culture material was controlled in a planned way, so that the culture material was fermented in 50-55 ℃ for 5-7 days, and then all the ventilation and air-extractor were pulled out. When the temperature of the culture material dropped rapidly below 28 ℃, the material was laid and sown in the room. For the secondary fermentation in the mushroom room, the pre-fermented culture material can be evenly spread on the bed frame. After sealing the doors and windows of the mushroom room, hot steam is injected into the mushroom room at a temperature of about 60 ℃, keeping it for 8 hours, then slowly cooling to 45 ℃, keeping it for 5 days, and quickly lowering the temperature to 28 ℃ to spread materials and sow seeds. 5.2. Preparation of cottonseed shell material cement land is selected as fermentation site, if it is not cement ground, a layer of plastic film should be laid. First clean the fermentation site, then spray 1000 times 80% deltamethrin, and then sprinkle a layer of quicklime powder. According to the time arrangement, the cottonseed shell and its auxiliary materials were mixed evenly to make the raw water Prida 1 ∶ 1.7-1.8. Before building the pile, use bricks to build the "non" shaped ventilation duct and build the pile with the ventilation duct as the center. The height of the pile is 1.2m, the width is 1.2m and 1.5m, the length is determined as appropriate, the top is tortoise back shape, and the smaller the edge slope is, the better. Then, spray 0.5% dichlorvos on the surface and cover the grass. When the temperature rises to 60 ℃, keep 18 hours for 24 hours, turn the pile for the first time and flatten it for the first time; when the temperature rises to 60 ℃, keep it for 18 hours for 24 hours, turn the pile for the second time, and turn it for 3 times. After each turn, 0.5% dichlorvos plus 80% deltamethrin was sprayed on the stack surface, and every 1m, the exhaust tube was placed on the ventilation duct during the fourth turn. After finishing the material pile, cover it with plastic film and leave the material surface 20~30cm. When the temperature in the distance rises to about 45 ℃, fumigate and ferment with 0.5 kg potassium permanganate + formaldehyde 1kg according to 5000kg material. In the meantime, the temperature is controlled at 45-55 ℃, and the air extractor is used to open and close to adjust the temperature. After 4 days and 5 days, unplug all ventilation ducts and extractors, and spread the material and sow seeds when the temperature of the material drops below 28 ℃. 6. One day before disinfection, laying, sowing and feeding, the mushroom room shall be disinfected and sterilized again. Press 1 cubic meter of space to fumigate with formaldehyde 10mL and potassium permanganate 5g. On the second day, the culture material with the temperature below 28 ℃ was laid flat on the mushroom bed and about 20cm thick. Before sowing, water can be transferred if the culture material is too dry, so that the water content of the culture material can reach 65% to 68%. Break the selected strain into particles, and disinfect all tools and hands with 1% potassium permanganate water. First, 50% of the bacteria are evenly mixed in the upper half of the material, and then 50% of the bacteria are scattered on the material surface, while 30% of the bacteria are evenly mixed in the upper half of the material, and then 70% of the high-quality bacteria are scattered on the material surface. Generally use 1.5 bottles of bacteria per square meter (750mL/ bottles). After sowing, leveling, gently compacting and covering the film. 7. Close the doors and windows within 3-5 days after covering the film, control the temperature at 25-26 ℃, and control the relative humidity at about 75%. When the material temperature exceeds 28 ℃, ventilation and cooling at night; when the material temperature is lower than 20 ℃, steam is used to heat it. When the basic cover of mycelium is about 7 days, the film is removed and the air is ventilated frequently. When the mycelium food has reached the depth of 1 stroke 2, pry the material layer once. During the germicidal period, prevent the occurrence of all kinds of miscellaneous bacteria and insect pests. On the same day after covering the film, 0.5% dichlorvos was sprayed on the walls, walkways and films of the mushroom room, 1000 times deltamethrin was sprayed on the second day, and once in 5-7 days. Generally, about 20 days, when the mycelium grows to the 2xp3 of the culture material, most of the bacteria scattered on the surface have spit yellow water, the hyphae become thick and white, and when the surface of the material has a sense of overall vibration, it shows that the bacteria have been well developed and can be covered with soil. 8. Covering soil according to local conditions, the covering materials of Pleurotus ostreatus used in our city are loam and imitation peat soil. Imitation peat soil formula: ① loam 4 cubic meters (100m2 culture material dosage), calcium magnesium phosphate fertilizer or calcium superphosphate 15kg, gypsum 17.5kg, dry fermented wheat straw coarse bran (when the culture material is fermented, it is made after being dried by crushing machine) 75kg, lime 15kg ② loam 4 cubic meters, calcium magnesium phosphate fertilizer or calcium superphosphate 17.5kg, gypsum 17.5kg, wheat bran 50kg, lime 15kg, wheat bran clean without mildew, soak in pH10 lime water for 1 day, remove and dry. On the other hand, the loam was taken from the soil below 30cm in the tillage layer 15 days before soil mulching, broken, shredded and sifted through 9 mesh. Three days before covering the soil, pile all kinds of soil covering materials on the cement floor according to the formula, mix well, spray and stack with 5% dichlorvos, build a long pile of 0.8m in height and width, cover it with plastic film for 24 hours, pre-wet with 5% lime water, and adjust pH7.5~8.0. When the water content reaches the hand, it will disperse as soon as it falls to the ground. After pre-wetting, the pile grows arched, used on the 2nd day. When covering the soil, the big particles are covered under the small ones, the loam is thick 3.3~3.5cm, and the imitation peat soil is thick 3.0~4.0cm, and the thickness of the covered soil should be uniform. 9. After mushroom management, dichlorvos was sprayed on the same day, 1000 times of deltamethrin was sprayed on the 2nd day, and water was diverted according to the mycelium growth after 3 days. The hyphae climb the soil quickly, grow vigorously, spray more water, and vice versa. The covering material is loam, the water spraying should be less and frequently, strictly prevent the soil layer from hardening, the total amount of water spraying should be less; the covering material is imitation peat soil, the times of spraying water is reduced, but the total amount of spraying water is more. Generally, within 2-3 days of water transfer, the bed surface is sprayed twice a day, each time the amount of water is 0.5~0.8kg/ square meters, and then the amount of water is gradually increased, and the water content of the overlying soil layer is fully adjusted in 3-4 days, but the water should not be allowed to infiltrate into the material. Ventilate after each spray to remove moisture from the surface of the soil. When the hand pinches the soil particles, it is flat but not scattered, and there is a slight crack, not sticky hands, and the water is adjusted when there is no dry heart in the soil particles. After the water transfer is over, close the doors and windows, hang the bacteria for 2 days, control the temperature at 22 ℃, and control the relative humidity at 80% 85%. When the temperature is higher than 30 ℃ and the humidity is less than 60%, the culture material should spray more water, and vice versa. When the hyphae climbed 3 / 4 of the soil, the soil began to be loosened. Spray 1000 times deltamethrin one day before loosening the soil. When loosening the soil, make the thickness of the soil layer uniform, properly mix the many and good parts of the soil with the small and poor hyphae, at the same time strengthen ventilation, inhibit the growth of hyphae, and promote the villous hyphae to kink into linear hyphae, and then form primordia. At this time, the temperature in the mushroom farm is controlled at 14: 18 ℃, and the relative humidity is kept at about 90%. Since then, spray water master mushroom spray more, mushroom less spray; spray more in the early stage, less spray in the later stage. In the early soil layer, one tide mushroom was sprayed with heavy water twice. When each tide mushroom grows to the size of soybeans, spray heavy water once, and spray heavy water again before clearing the bed. The amount of water sprayed is 1.3~1.8kg/ square meters. In the later stage, the amount of spraying water should be relatively reduced, and the method of light and diligent spraying should be adopted. After Pleurotus ostreatus was unearthed until harvested, the humidity was controlled at 90% to 95%. When the harvest peak of each tide mushroom is over, the humidity can be reduced to 85%-90%, the ground is no longer sprayed, and the ventilation of the mushroom room is increased. In general, ventilation should be strengthened in the early stage. When the mushroom room exceeds 18 ℃, the ventilation of the mushroom room should be carried out at night and on rainy days. When there is no wind, all the north and south windows are open; when there is wind, only leeward windows are opened. In the later stage, the ventilation of mushroom room should be reduced gradually. Ventilation during the day when the temperature drops below 14 ℃. If there are long-stalked small cover mushrooms, thin mushrooms, red mushrooms, rust spot mushrooms need timely ventilation; there are small mushrooms, thin mushrooms, open umbrellas, empty roots, when the single mushroom is light, the wind should be controlled. 10. When the fresh harvest is sold on the market, the size can be harvested when the bacterial curtain is not broken or the umbrella is not opened; canned and salted mushrooms are harvested when the cap diameter is 1.5~4.0cm, the mushroom shape is round, the color is white, there is no hollow root, and there is no insect moth or damage. The bed is not sprayed with water before harvest. When the fruiting body grows fast, it should be harvested 2 times and 3 times in one day. There are two harvesting methods: rotation method and mushroom pulling method. When the mushroom is dense, the spinning mushroom method is used, that is, the mushroom is picked gently; when the mushroom is sparse, the mushroom is pulled up directly; when many mushrooms are formed, the standard fruiting body is cut down with a small knife to keep the fruit body small. When picking mushrooms, handle them carefully so as not to damage the mushroom body.

- Prev

High-yielding cultivation techniques of two Tides of Pleurotus ostreatus

Brown rot, also known as white rot, wet bubble disease, blister disease, etc., diseased mushrooms are soaked when young, the disease is caused by a pathogen called verrucosporium. In the later stage, it forms irregular gray-white "pimple head" or deformed mushroom, and gives birth to a layer of "white hair" on the surface. That is, when the temperature of the pathogenic mycelium is above 20 ℃, it takes only 4-5 days.

- Next

High-yield cultivation techniques of Pleurotus ostreatus

Pleurotus ostreatus, also known as white mushroom, foreign mushroom, mushroom, etc., is the most widely cultivated species, its meat is fresh and tender, delicious, rich in protein and a variety of essential amino acids and trace elements, and has a certain medical value, so it is more and more popular among people. First, the cultivation season.

Related

- Fuxing push coffee new agricultural production and marketing class: lack of small-scale processing plants

- Jujube rice field leisure farm deep ploughing Yilan for five years to create a space for organic food and play

- Nongyu Farm-A trial of organic papaya for brave women with advanced technology

- Four points for attention in the prevention and control of diseases and insect pests of edible fungi

- How to add nutrient solution to Edible Fungi

- Is there any good way to control edible fungus mites?

- Open Inoculation Technology of Edible Fungi

- Is there any clever way to use fertilizer for edible fungus in winter?

- What agents are used to kill the pathogens of edible fungi in the mushroom shed?

- Rapid drying of Edible Fungi