High-yielding cultivation techniques of two Tides of Pleurotus ostreatus

1. in that past, most of the mushroom shed used for mushroom shed treatment were simple greenhouses with single slope or semi-underground simple greenhouses, and it was difficult to use sunlight to increase temperature in low temperature season, so that after cultivation and production entered November, the temperature of the shed decreased with the temperature, and when the lowest temperature of the shed reached 8℃, the mushrooms would no longer be produced, and only after the temperature rose again in March of the next year could the mushrooms be produced again, which would certainly prolong the fruiting period. After the mushroom shed was reconstructed to imitate winter warm or sunlight warm (winter warm), the low temperature time of more than two months from the middle of December to the last ten days of February could be fully utilized for mushroom production, and the mushroom production time was prolonged. The basic practice is: first according to the production plan to rebuild the original shed or directly new, wall thickness is not less than 0.8 meters, the highest part of the shed is not less than 2.5 meters, generally about 40 meters long, 6 meters wide-7 meters is appropriate, using "two films and two covers" cover, hanging a layer of black plastic film in the shed, so that when the cover is uncovered in the low temperature season, heat can be allowed to enter without direct sunlight. Secondly, according to the cultivation bed line digging ditch, generally north-south to the bed width of 1.2 meters, operation channel width of 0.4 meters-0.6 meters, the operation channel digging depth of about 0.2 meters, close to the south can gradually deepen, bed slightly turtle-back shape. Third, disinfection. New mushroom shed can be sprayed with 40 - 60 times mushroom disease-eliminating king solution and 600 times dichlorvos solution, and then closed mushroom shed, two days later can be used. Reapply the pesticide once every other day in the reconstructed shed to strengthen the disinfection and insecticidal effect. Finally, the shed is watered. About 5 days before feeding and sowing, irrigate the shed and allow it to flow naturally to make the land fully irrigated. One is to increase the humidity in the shed, and the other is to reduce the temperature of the shed. 2. Cultures are processed according to the preparation or storage of raw materials, and the appropriate formula is selected. Two formulas are provided for selection: ① Formula 1: wheat straw 3000kg, cow dung 3000kg, calcium superphosphate 60kg, urea 60kg, lime powder 80kg, gypsum powder 80kg, light calcium carbonate 90kg, bean cake powder 100kg, edible fungi three-dimensional nutrient essence (mixed type) 10 bags. (2) Formula 2: corncob powder 2000 kg, cottonseed hull 2000 kg, cow dung 2000 kg, calcium superphosphate 80 kg, urea 40 kg, lime powder 60 kg, gypsum powder 80 kg, light calcium carbonate 50 kg, bean cake powder 60 kg, edible fungi three-dimensional nutrient essence (mixed type) 12 bags.

- Prev

Management of Pleurotus ostreatus emergence in Autumn

Pleurotus ostreatus belongs to medium and low temperature type mushrooms. The protein content of fresh mushrooms is 35%-38%, and its nutritional value is 412 times that of vegetables and fruits. It enjoys the laudatory names of "health food" and "king of vegetarian", and is favored by domestic and foreign markets. Pleurotus ostreatus is planted in Beijing, and the mushroom emergence period is from September to November and from April to May of the following year. Double.

- Next

High-yield cultivation of Pleurotus ostreatus in bed frame

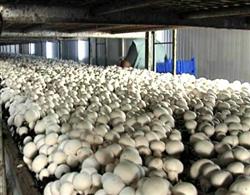

1. Mushroom house and bed frame structure mushroom house is 19.6m long from east to west, 9m wide from north to south, 2.5m high from front and rear wall and 3.5m high from gable. The wall is bricked with lime. Put cement on the outside; wipe it with lime mud on the inside, then brush it with lime mud. There are 4 25cm × 20cm ventilation windows up and down the front and rear walls facing the aisle. The first one passes through.

Related

- Fuxing push coffee new agricultural production and marketing class: lack of small-scale processing plants

- Jujube rice field leisure farm deep ploughing Yilan for five years to create a space for organic food and play

- Nongyu Farm-A trial of organic papaya for brave women with advanced technology

- Four points for attention in the prevention and control of diseases and insect pests of edible fungi

- How to add nutrient solution to Edible Fungi

- Is there any good way to control edible fungus mites?

- Open Inoculation Technology of Edible Fungi

- Is there any clever way to use fertilizer for edible fungus in winter?

- What agents are used to kill the pathogens of edible fungi in the mushroom shed?

- Rapid drying of Edible Fungi