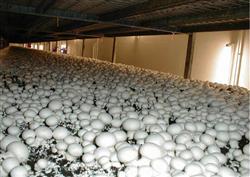

Main Points of Production of Original and Cultivated Species of Agaricus bisporus

The formulation and treatment of wheat grain culture medium: 100 kg of wheat grain, 10 kg of dry dung grass or bran shell after fermentation. Calcium carbonate or stone powder 1kg to 2kg. The wheat grain is rich in nutrition and the mycelium grows vigorously. In order to prevent the premature senescence of mycelium vitality, 50 grams of magnesium sulfate and 100 grams of potassium dihydrogen phosphate are added in every 100 kilograms of wheat grain. The grain of wheat is full and thick, and there is no worm-eaten grain. Generally, the soaking effect of aged wheat in the next year after dormancy stage is good, and the water absorption and softening is fast. Soak the wheat grain in 1%-2% lime water, the water surface should be 10-15 cm higher than the wheat grain, and often stir, remove the floating grains and control the soaking time flexibly according to the water temperature. When the inner part of the wheat grain is soaked until there is no white heart, it will take about 12 to 14 hours when the water temperature is about 26 degrees Celsius. The soaked wheat grains are drained and blown on a clean cement floor. after the surface moisture of the wheat grains is properly dried, you can mix in pre-wet dung grass filling grains, stone high powder and so on. According to the standard of controlling the water absorption of wheat grain in a strain bottle, the wet weight reaches 136 to 140 kg per 100 kg wheat grain after water absorption and air drying. The wheat grains can also be soaked in clear water for about 8 hours, and then boiled in boiling water for 15 to 20 minutes. When the wheat grain is fully cooked (without white heart), remove and drain the water and spread it out. When the moisture on the surface of the wheat grain is properly dried, then mix the ingredients according to the above-mentioned method. In this method, even treatment of wheat grains with water is beneficial to the development of bacteria. The moisture content of wheat grain must be moderate after absorbing water and adjusting moisture. Too low water content, hard texture, difficult to penetrate sparse bacteria, small number of reproduction, easy to infect bacteria after sowing; too high water content, soft bubbles in texture, easy to break during sterilization, starch exudation paste, easy to make wheat grains agglomerate, fungus cover phenomenon will be produced after mycelium spread. In addition, the water content of pre-wetted fillers should be close to that of wheat grains. Filling material or called sealing material, guide material, bridge material, etc. It can fix grain culture medium and reduce the gap between grains, which is beneficial to seed block colonization and food cover, beneficial mycelium spread and growth evenly, and avoid mycelium fracture or fungus quilt caused by grain loosening. The commonly used fillers are dung grass, soil, grain chaff, husk and so on. The amount of fillers accounts for about 10% to 20% of the grain medium. The general requirements are relatively short, it is best to go through the development of fermentation, the preparation of mixing, the moisture content after wetting requires the relative consistency of grain water content. The filling grains of fermented dry storage are not moldy. The material that is too long and too thick should be crushed, and the dung grass should be pre-wet with lime water and PH8 about 4 hours before the wheat grain is blown. The dung grass with a moisture content of 55% is used as a filling material to mix well with wheat grains, gypsum powder, etc., and then bottled, and then half of the dung grass is used as the surface sealing material of the matrix. The wheat grain medium should vibrate up and down when it is sub-packed, so that the matrix can be combined relatively tightly, after the end of the sub-package, there is no need to drill holes and can be sterilized according to the routine, and after cooling, it can be put into the provenance. This method is labor-saving and convenient, and is commonly used in the large-scale production of wheat grain medium. Sterilization time: the structure of wheat grain is compact, the heat penetration is slow, the sterilization time is long, and the effect of high pressure sterilization is better. Usually 1.5 kg pressure to maintain more than 3 hours, atmospheric pressure sterilization 100 degrees Celsius to maintain more than 10-12 hours. Preparation of cottonseed hull culture medium cottonseed hull is a granular structure raw material, and its nutritional composition is reasonable. The mycelium is not easy to grow, and it is a widely used culture material for edible bacteria. Cottonseed shell is used as the medium to produce mushroom strains. Generally, 1 bottle of cottonseed shell bacteria can be used instead of 2 / 2. 5 bottles of dung grass bacteria. When fermented cottonseed shell is used as culture medium, the following methods can be used: 100 kg of cottonseed hull, 10 kg of dried pig and cow dung powder, 3 kg of stone powder, 0.5 kg of superphosphate and 4 kg of lime. First, the cottonseed shell, dry dung powder and half of the stone powder are pre-wet with lime water or river mud water to make their water content of 60% to 65%. After mixing well, the pile is built. The heap is 1 meter high and 1.3 to 1.5 meters high. After building the stack, cover the film and punch holes in the stack every 25 to 30 centimeters apart. To facilitate breathable fermentation, remove the pile when the cottonseed shell is fermented evenly and the appearance is reddish brown. Break it up and dry it. Before use, adjust the humidity with lime water about 4 hours in advance. Make its water content reach 55% 60%, PH 8.5-9, sterilize 1.5 kg and keep pressure 3-3.5 hours after sub-packing. Before inoculation, the bottle temperature must be reduced to about 30 degrees Celsius to prevent high temperature inoculation of heat-dead bacteria. After cooling and inoculation, each mother seed can be transferred to 3 or 4 bottles of original seed, first clean the inoculation box (room) before vaccination and spray 2% of the seed. Then move all the sterilized bacteria bottles and tools into it, and then strictly disinfect the inoculation box (room) according to the routine. Vaccination should be carried out in strict accordance with aseptic operation. The inoculant takes the seed block and opens the original bottle cork at the same time. The inoculator takes out the strain block, quickly connects it to the original seed bottle, and then plugs the cotton cork through the flame.

- Prev

The cultivation of Pleurotus ostreatus is divided in autumn, so it is very important.

Soil mulching is a unique technical measure in the production of Pleurotus ostreatus. Attention should be paid to the following aspects before covering the soil: (1) the surface of the culture material should be kept dry and ventilated if the material surface is too wet. (2) to check whether there are miscellaneous bacteria and pests, once found, measures must be taken. (3) the material noodles should be carried out once.

- Next

Disease and pest control of blue lily (love flower)

The name Agapanthus comes from the Greek god of love, agap é and the god of flowers, anthos, but in fact, the reason why the flower is called "flower of love" is a long-forgotten mystery. In 1788, L'Heritier established the African lily genus. It was once classified as the Liliaceae, and then into the Liliaceae.

Related

- Fuxing push coffee new agricultural production and marketing class: lack of small-scale processing plants

- Jujube rice field leisure farm deep ploughing Yilan for five years to create a space for organic food and play

- Nongyu Farm-A trial of organic papaya for brave women with advanced technology

- Four points for attention in the prevention and control of diseases and insect pests of edible fungi

- How to add nutrient solution to Edible Fungi

- Is there any good way to control edible fungus mites?

- Open Inoculation Technology of Edible Fungi

- Is there any clever way to use fertilizer for edible fungus in winter?

- What agents are used to kill the pathogens of edible fungi in the mushroom shed?

- Rapid drying of Edible Fungi